+86 15858532562

| Size: | |

|---|---|

| Material: | |

| Availability: | |

| Quantity: | |

FOGO

Lift check valve

Francois

WCB,304,316,A105

1 year

Purpose and functions:

The function of the check valve is to allow the medium to flow in only one direction, and to prevent the reverse flow.

Usually this valve is automatic operation, under the action of fluid pressure flowing in one direction, the valve disc opens; When the fluid flows in the opposite direction, the fluid pressure and the self-coincidence valve disc act on the seat, thus cutting off the flow. Swing check valves have a hinged mechanism and a door-like disc that rests freely on the inclined seat surface. To ensure that the disc reaches the proper position on the seat surface each time, the disc is designed in a hinged mechanism so that the disc has enough space to swing and allow the disc to make true, full contact with the seat. The disc can be made entirely of metal, or the metal can be inlaid with leather, rubber, or a synthetic cover, depending on the performance requirement.

With the swing check valve fully open, the fluid pressure is virtually unimpeded, so the pressure drop through the valve is relatively small.

The disc of the lift check valve is located on the seat sealing surface of the valve body. In addition to the valve disc can be lifted freely, the rest of the valve is like a globe valve, fluid pressure causes the valve disc to lift from the seat sealing surface, and the media backflow causes the valve disc to fall back to the seat and cut off the flow.

Depending on the conditions of use, the disc can be an all-metal structure, or it can be in the form of a rubber pad or rubber ring mounted on the disc holder. Like the globe valve, the passage of fluid through the lift check valve is narrow, so the pressure drop through the lift check valve is greater than that of the swing check valve, and the flow rate of the swing check valve is less restricted.

Installation mode:

Lift type check valve: the valve disc slides along the vertical center line of the valve body, the internal thread check valve can only be installed on the horizontal pipe, and the valve disc can be used in the high pressure small diameter check valve. The body shape of the butterfly check valve is the same as that of the globe valve (which can be used in common with the globe valve), so its fluid resistance coefficient is larger. Its structure is similar to the globe valve, and the valve body and disc are the same as the globe valve. The upper part of the valve disc and the lower part of the valve cover are processed with a guide sleeve, and the valve disc guide can be lifted and lifted freely in the valve disc guide. When the medium flows along, the valve disc is opened by the thrust of the medium, and when the medium stops flowing, the valve disc lands on the valve seat by self-drooping to prevent the reverse flow of the medium. The direction of medium inlet and outlet channel of straight-through butterfly check valve is perpendicular to the direction of valve seat channel; Vertical lift check valve, the medium inlet and outlet channel direction is the same as the seat channel direction, the flow resistance is smaller than the straight-through type.

Lift check valve: Valve with disc sliding along the center line of the body. Pipe type check valve is a new valve, its small size, light weight, good processing technology, is one of the development direction of check valve. However, the fluid resistance coefficient is slightly larger than that of the swing check valve

Design Standards:

Structure length: API594, API6D, DIN3202, JB/T8937.

Pressure-temperature class: SNSIB16.34, DIN2401, GB/T9124, HG20604, HG20625, SH3406, JB/T74.

Test and inspection: API598, JB/T9092.

Piping flange: JB/T74~90、GB/T9112!9124、HG20592~20635、SH3406、ANSIB16.5、DIN2543~2548、GB/T13402、API605、ASMEB16.47

Installation and maintenance:

Both ends of the valve path must be blocked, there is a dry and ventilated room. If it is stored for a long time, it should be checked frequently to prevent corrosion.

The valve should be cleaned before installation, and the defects caused in the transportation process should be eliminated.

The installation must carefully check whether the mark and nameplate on the valve meet the requirements of use.

Lift type vertical flap check valve should be installed on the horizontal pipe.

The lifting type horizontal flap check valve should be installed on the vertical pipe.

Do not make the check valve bear weight in the pipeline, the large check valve should be independently supported, so that it is not affected by the pressure generated by the pipe system.

When installing the check valve, special attention should be paid to the flow direction of the medium, the normal flow direction of the medium should be consistent with the direction of the arrow indicated on the valve body, otherwise it will cut off the normal flow of the medium.The bottom valve should be installed at the bottom of the water pump suction pipe.

The general lift check valve should be installed on the horizontal pipe, the vertical lift check valve and the bottom valve are generally installed on the vertical pipe, and the medium flows from bottom to bottom.

When the check valve is closed, water hammer pressure will be generated in the pipeline, which will cause serious damage to the valve, pipeline or equipment, especially for the large mouth pipeline or high pressure pipeline, so it should be caused by the check valve selector's high attention.

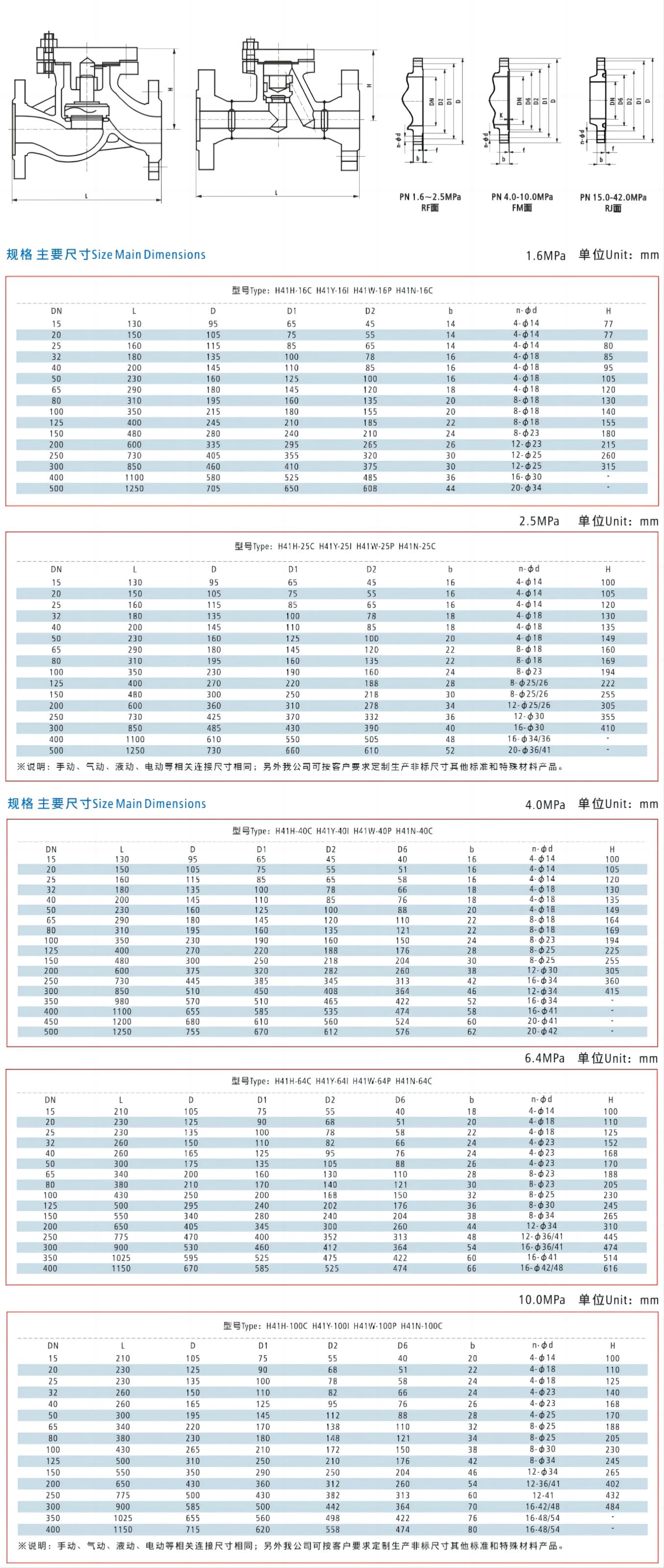

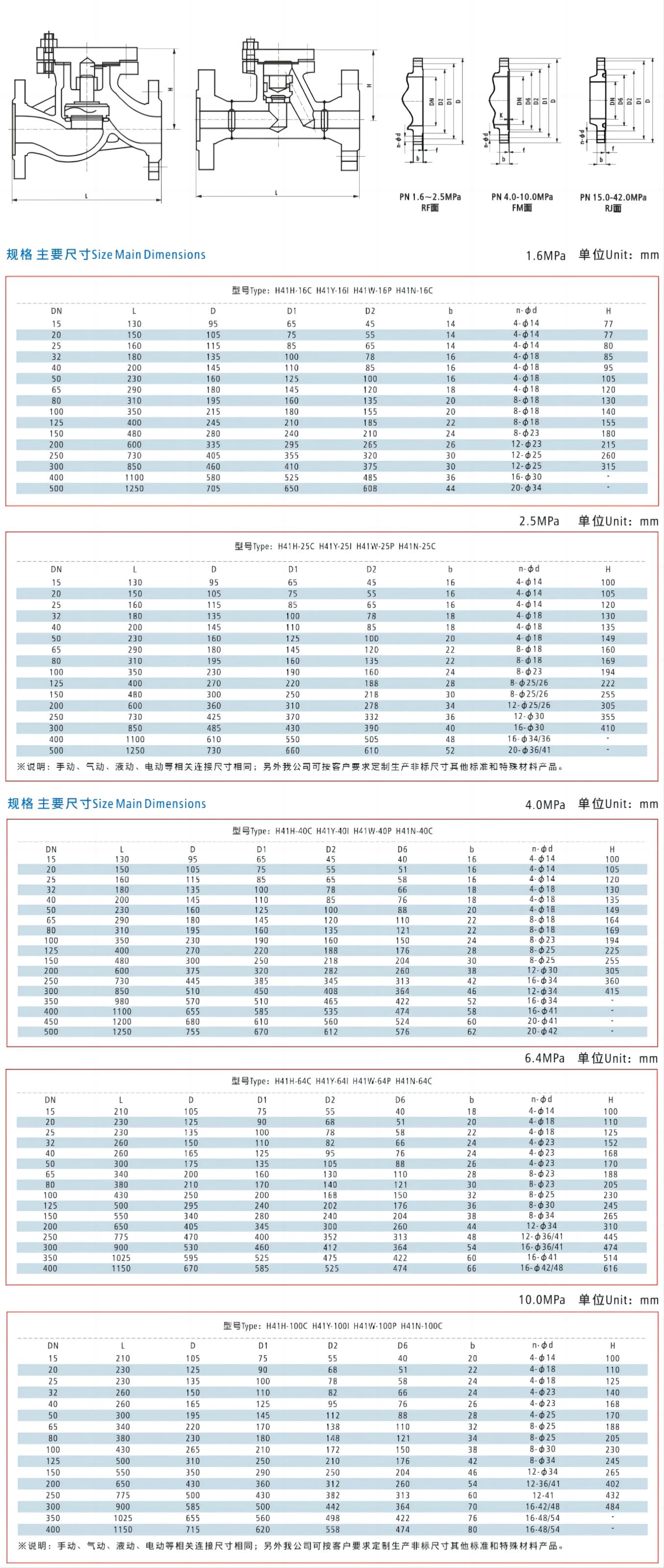

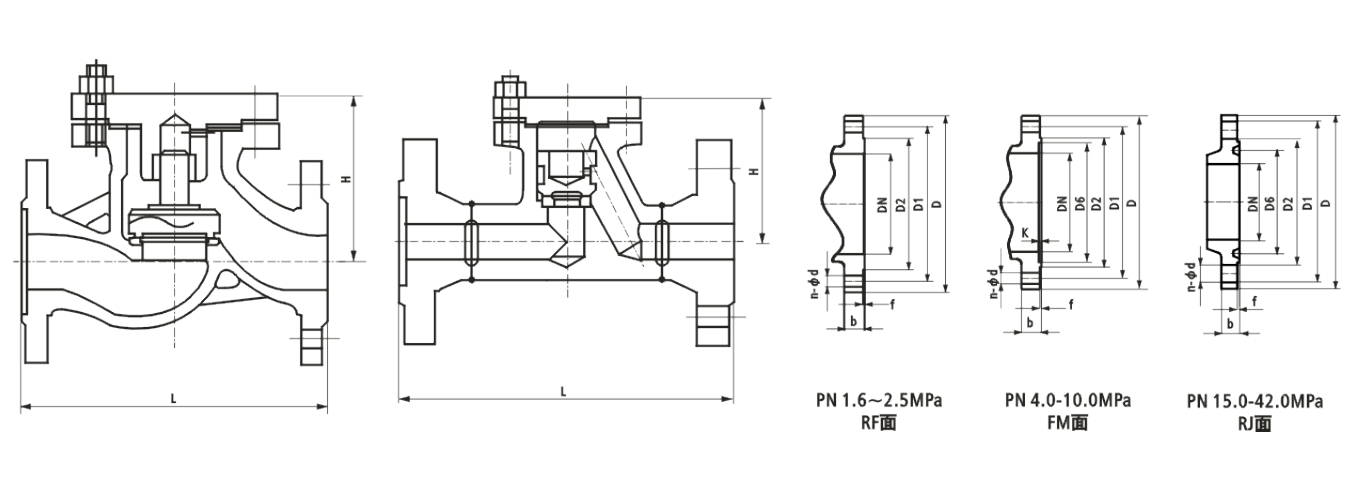

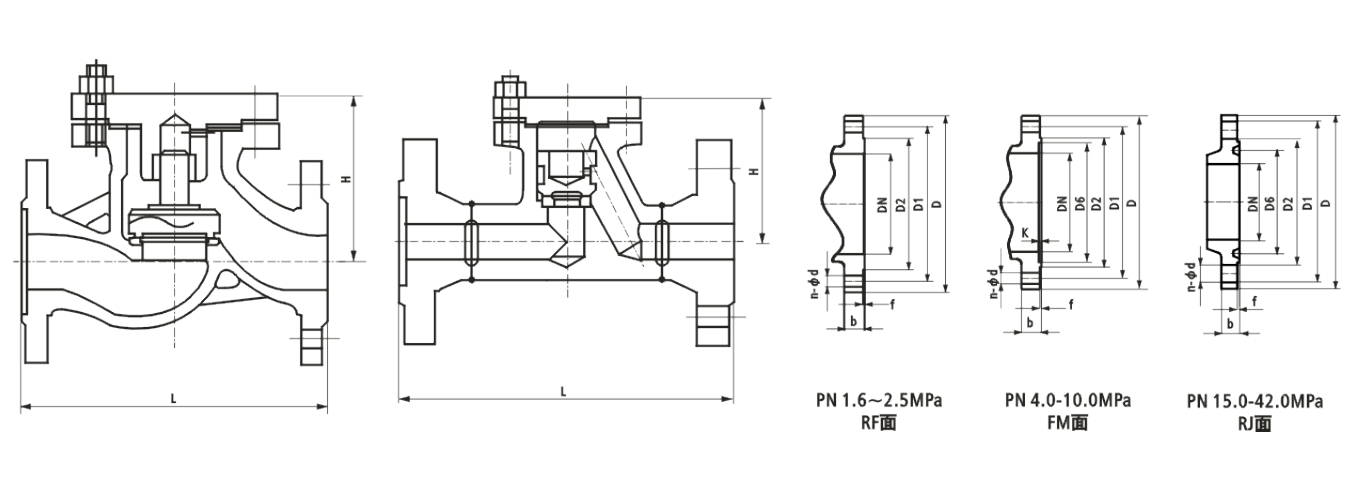

Specification

| Item | Lift check valve |

| Product name | Lift check valve |

| Material | WCB,304/316,A105 |

| Size | DN15 to DN1000 |

| End Connection | Flanged |

| Pressure range | 0.6Mpa、1.0Mpa、1.6Mpa、2.5Mpa |

| Surface | Inner Ra.0.8um or specified |

| Standard | 3A, DIN, SMS, BS/RJT, ISO/IDF, ASME/BPE etc. |

| Gasket | PIFE, EPDM, Buna-N, Silicone, FPM etc. |

| Customized support | OEM |

| Media | Water, Oil, Gas, Air |

| Place of Origin | China |

| Certification | ISO 9001,CE,TUV,SGS |

| Application | For use in harsh oil and gas fields |

Body Type

About Delivery

About Application

Purpose and functions:

The function of the check valve is to allow the medium to flow in only one direction, and to prevent the reverse flow.

Usually this valve is automatic operation, under the action of fluid pressure flowing in one direction, the valve disc opens; When the fluid flows in the opposite direction, the fluid pressure and the self-coincidence valve disc act on the seat, thus cutting off the flow. Swing check valves have a hinged mechanism and a door-like disc that rests freely on the inclined seat surface. To ensure that the disc reaches the proper position on the seat surface each time, the disc is designed in a hinged mechanism so that the disc has enough space to swing and allow the disc to make true, full contact with the seat. The disc can be made entirely of metal, or the metal can be inlaid with leather, rubber, or a synthetic cover, depending on the performance requirement.

With the swing check valve fully open, the fluid pressure is virtually unimpeded, so the pressure drop through the valve is relatively small.

The disc of the lift check valve is located on the seat sealing surface of the valve body. In addition to the valve disc can be lifted freely, the rest of the valve is like a globe valve, fluid pressure causes the valve disc to lift from the seat sealing surface, and the media backflow causes the valve disc to fall back to the seat and cut off the flow.

Depending on the conditions of use, the disc can be an all-metal structure, or it can be in the form of a rubber pad or rubber ring mounted on the disc holder. Like the globe valve, the passage of fluid through the lift check valve is narrow, so the pressure drop through the lift check valve is greater than that of the swing check valve, and the flow rate of the swing check valve is less restricted.

Installation mode:

Lift type check valve: the valve disc slides along the vertical center line of the valve body, the internal thread check valve can only be installed on the horizontal pipe, and the valve disc can be used in the high pressure small diameter check valve. The body shape of the butterfly check valve is the same as that of the globe valve (which can be used in common with the globe valve), so its fluid resistance coefficient is larger. Its structure is similar to the globe valve, and the valve body and disc are the same as the globe valve. The upper part of the valve disc and the lower part of the valve cover are processed with a guide sleeve, and the valve disc guide can be lifted and lifted freely in the valve disc guide. When the medium flows along, the valve disc is opened by the thrust of the medium, and when the medium stops flowing, the valve disc lands on the valve seat by self-drooping to prevent the reverse flow of the medium. The direction of medium inlet and outlet channel of straight-through butterfly check valve is perpendicular to the direction of valve seat channel; Vertical lift check valve, the medium inlet and outlet channel direction is the same as the seat channel direction, the flow resistance is smaller than the straight-through type.

Lift check valve: Valve with disc sliding along the center line of the body. Pipe type check valve is a new valve, its small size, light weight, good processing technology, is one of the development direction of check valve. However, the fluid resistance coefficient is slightly larger than that of the swing check valve

Design Standards:

Structure length: API594, API6D, DIN3202, JB/T8937.

Pressure-temperature class: SNSIB16.34, DIN2401, GB/T9124, HG20604, HG20625, SH3406, JB/T74.

Test and inspection: API598, JB/T9092.

Piping flange: JB/T74~90、GB/T9112!9124、HG20592~20635、SH3406、ANSIB16.5、DIN2543~2548、GB/T13402、API605、ASMEB16.47

Installation and maintenance:

Both ends of the valve path must be blocked, there is a dry and ventilated room. If it is stored for a long time, it should be checked frequently to prevent corrosion.

The valve should be cleaned before installation, and the defects caused in the transportation process should be eliminated.

The installation must carefully check whether the mark and nameplate on the valve meet the requirements of use.

Lift type vertical flap check valve should be installed on the horizontal pipe.

The lifting type horizontal flap check valve should be installed on the vertical pipe.

Do not make the check valve bear weight in the pipeline, the large check valve should be independently supported, so that it is not affected by the pressure generated by the pipe system.

When installing the check valve, special attention should be paid to the flow direction of the medium, the normal flow direction of the medium should be consistent with the direction of the arrow indicated on the valve body, otherwise it will cut off the normal flow of the medium.The bottom valve should be installed at the bottom of the water pump suction pipe.

The general lift check valve should be installed on the horizontal pipe, the vertical lift check valve and the bottom valve are generally installed on the vertical pipe, and the medium flows from bottom to bottom.

When the check valve is closed, water hammer pressure will be generated in the pipeline, which will cause serious damage to the valve, pipeline or equipment, especially for the large mouth pipeline or high pressure pipeline, so it should be caused by the check valve selector's high attention.

Specification

| Item | Lift check valve |

| Product name | Lift check valve |

| Material | WCB,304/316,A105 |

| Size | DN15 to DN1000 |

| End Connection | Flanged |

| Pressure range | 0.6Mpa、1.0Mpa、1.6Mpa、2.5Mpa |

| Surface | Inner Ra.0.8um or specified |

| Standard | 3A, DIN, SMS, BS/RJT, ISO/IDF, ASME/BPE etc. |

| Gasket | PIFE, EPDM, Buna-N, Silicone, FPM etc. |

| Customized support | OEM |

| Media | Water, Oil, Gas, Air |

| Place of Origin | China |

| Certification | ISO 9001,CE,TUV,SGS |

| Application | For use in harsh oil and gas fields |

Body Type

About Delivery

About Application