+86 15858532562

Views: 3 Author: Site Editor Publish Time: 2024-05-27 Origin: Site

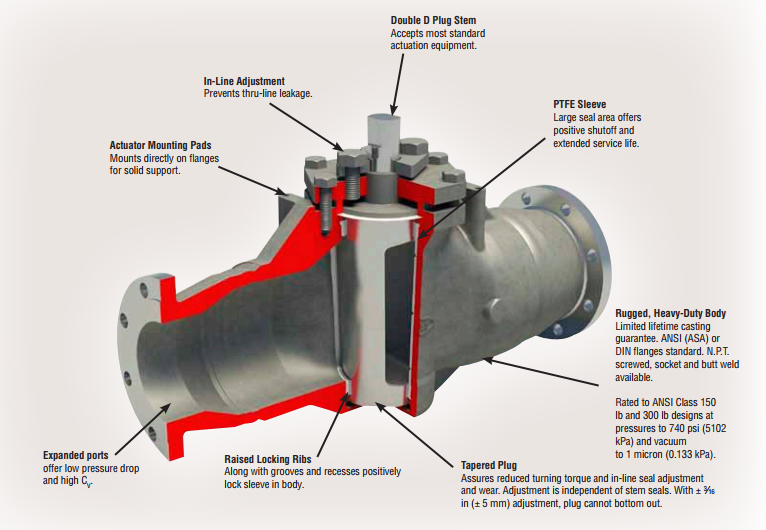

Plug valve is a valve that uses a plug body with a through hole as the opening and closing part. The plug body rotates with the valve stem to achieve opening and closing actions. Small unpacked plug valves are also called "cock". The plug body of the plug valve is mostly a cone (there are also cylinders), which cooperates with the conical hole surface of the valve body to form a sealing pair. Plug valve is the earliest type of valve with simple structure, fast opening and closing, and low fluid resistance. Ordinary plug valves are sealed by direct contact between the precision-machined metal plug body and the valve body, so the sealing performance is poor, the opening and closing force is large, and it is easy to wear. It can usually only be used in low (not higher than 1 MPa) and small applications. diameter (less than 100 mm). In order to expand the application range of plug valves, many new structures have been developed. Oil-lubricated plug valves are one of the most important. Special grease is injected from the top of the plug body between the taper hole of the valve body and the plug body to form an oil film to reduce the opening and closing torque and improve sealing and service life. Its working pressure can reach 64 MPa, its maximum operating temperature can reach 325°C, and its maximum diameter can reach 600 mm. Plug valve passages come in many forms. The common straight-through type is mainly used to cut off fluid. Three-way and four-way plug valves are suitable for fluid reversing. The opening and closing part of the plug valve is a cylinder with a hole, which rotates around an axis perpendicular to the channel to achieve the purpose of opening and closing the channel. Plug valves are mainly used to open and close pipelines and equipment media.

The main advantages of plug valves are as follows:

1. Suitable for frequent operations, opening and closing quickly and easily.

2. Small fluid resistance.

3. Simple structure, relatively small size, light weight and easy to maintain.

4. Good sealing performance.

5. It is not restricted by the installation direction, and the flow direction of the medium can be arbitrary.

6. No vibration and low noise.

7. Plug valves can be divided into four types according to their structural forms: tight-fitting plug valves, self-sealing plug valves, packing plug valves and oil-filled plug valves. According to the channel form, it can be divided into three types: straight-through type, three-way type and four-way type.